Blog

Operational Excellence in Action: Keeping Labs Running Year-Round

While the rest of Southern Africa virtually shuts down, laboratories must maintain continuous mining operations through December and January.

South African mining labs operate around the clock, often adjusting staff roster but rarely stopping. They deliver critical results that keep production on track. Although individual mining lab operational schedules may vary, the sector’s commitment to uninterrupted service is clear. Operational excellence is continuous, not seasonal.

In this post, we share practical strategies for lab managers to maintain operational excellence during the festive season.

Why Labs Continue to Deliver Results Through December–January

Mining laboratories run 24 hours a day and 365 days a year. Managers may take limited leave, usually only on Christmas Day, but they ensure full coverage through careful rotation.

This consistency underpins mining laboratory management and keeps testing lines stable even when the wider industry pauses.

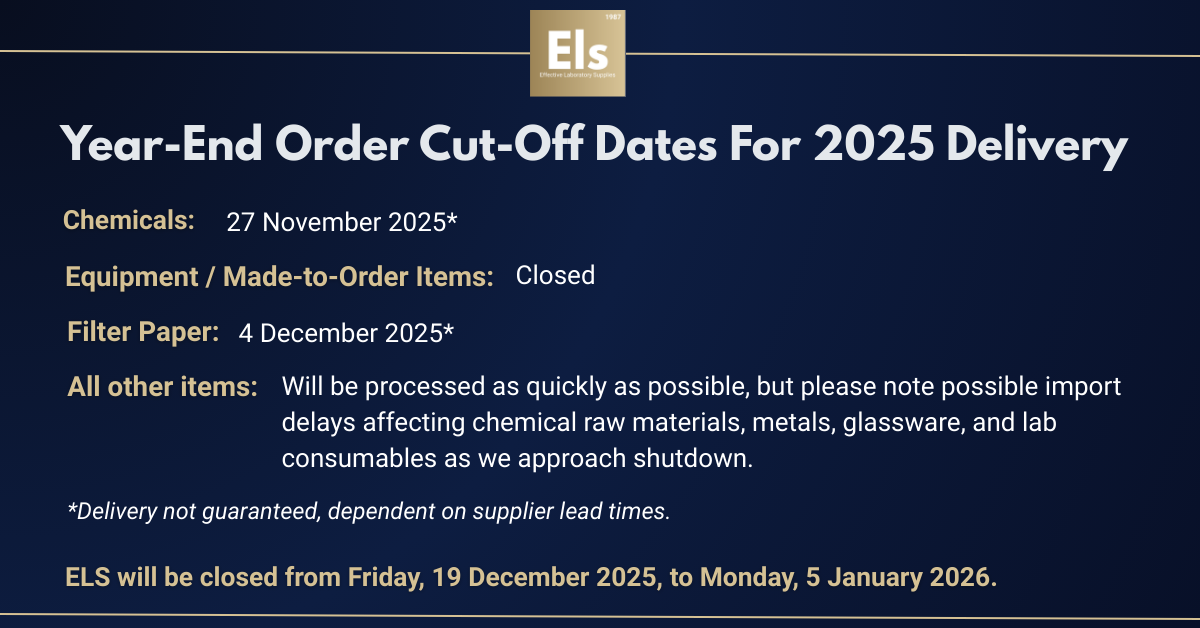

How to Navigate Supplier Shutdowns and Operational Pressures

The most significant pressure at year-end comes from supplier shutdowns rather than the labs themselves. Manufacturing and service partners often close for annual leave.

Mines that achieve reliable performance prepare early for these breaks. Strategic lab procurement strategies make a measurable difference, especially for operations that cannot afford delays.

By following these insights, lab managers can ensure their laboratories continue to deliver critical results without interruption, even when suppliers and many of the supporting industries pause for holidays.

Order Consumables and Stock Critical Spares

Experienced labs place bulk orders to cover December through January, often extending into February. Suppliers take time to return to full capacity, so planning is essential. Mining lab procurement teams typically begin new season ordering in late February. Managers also review all PPE to ensure staff safety and compliance.

Field Reality: Lab Teams Keep Working

Because labs operate continuously, staff rotate leave through the festive period. Managers adjust rosters to maintain safe coverage. High morale matters: simple gestures like biscuits or cold drinks help teams feel supported. People remain the backbone of operational excellence and the heart of mining lab operations support.

Reliability, Planning, and People

Forward planning is the foundation of reliability. As David Harvey, Technical Director, notes: “If you don’t plan early, you sit with consequences for 6–8 weeks.” Planning includes advance servicing of instrumentation, ideally in October or November, to prevent festive breakdowns. Redundancy systems, such as dual ICPs or XRFs, strengthen reliability and reduce risk.

Reliability by Design

Critical equipment should be serviced before mid-December. Plant shutdowns can create valuable windows for maintenance and training. Preventive maintenance also protects warranties and avoids costly setbacks. Environmental systems need careful attention, too. Managers should confirm airflow in fume cupboards and extraction systems using a manometer or even a simple paper test.

Importance of Multi-skilled Staff

Effective rotation requires well-trained substitutes. Plant shutdowns offer ideal opportunities for skills development. Competent, multi-skilled teams protect the continuity that continuous mining operations rely on.

Safety and the Lab Manager

All SOPs should be current before managers take leave. Senior staff can refine procedures during quieter periods. “Safety is non-negotiable. If a lab manager doesn’t make safety their top priority, they shouldn’t be a lab manager.”

From Reflection to Readiness

December encourages reflection on the year’s achievements. January focuses on readiness for renewed production. Before restarting after any slowdown, labs should follow a detailed checklist that verifies power, gas supply, extraction, chillers, and controlled ramp-up of equipment like XRFs. Reliability in 2026 begins with today’s preparation.

Hurry! There’s still time to squeeze in some final orders.